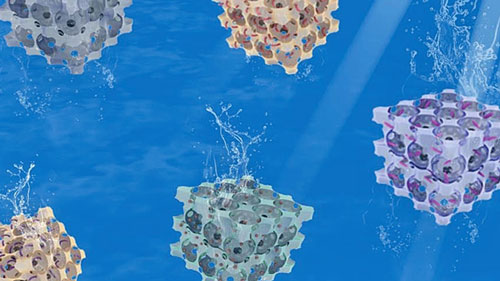

Oxygen-delivering hydrogel could help regenerate damaged cartilage in joints, is useful in treatment of Parkinson’s disease, accelerates diabetic wound healing, and more

Oxygen-delivering hydrogel accelerates wound healing. Jianjun Guan, professor of mechanical engineering and materials science at the McKelvey School of Engineering at Washington University in St. Louis, has developed a hydrogel that delivers oxygen to a wound, which decreases inflammation, helps remodel tissue and accelerates healing.

The following written content from Nonowerk

Hydrogels are fascinating natural or synthetic polymer materials that exhibit very versatile chemistries and physical or biological properties. They are 3D networks of either physically or chemically crosslinked polymers that resemble organic tissues and that can hold large amounts of water within their interlocked molecular network.

These soft, translucent materials swell or shrink in response to water absorption or desorption and can hold a large amount of water without losing their structural integrity.

Hydrogels were first proposed for biological use in 1960. In order for a material to be considered a hydrogel, water must constitute at least 10% of its total weight or volume.

he ability of hydrogels to absorb water arises from hydrophilic functional groups attached to the polymeric backbone, while their resistance to dissolution arises from cross-links between network chains. Many materials, both naturally occurring and synthetic, fit the definition of hydrogels.

Natural hydrogels include collagen, silk fibroin, hyaluronic acid, chitosan, alginate and hydrogels derived from decellularized tissues. Their unique properties include: biocompatibility, biodegradability, low cytotoxicity, the possibility to tailor the hydrogel into an injectable gel and their similarity to physiological environment.

However, natural hydrogels do have some limitations, for example they do not have strong mechanical properties and are not easily controllable due to their batch-to-batch variation. For these reasons, natural hydrogels are often combined to synthetic ones, creating composite polymers.

Hydrogels have become a highly relevant biochemical scaffold due to their tunable properties, inherent biocompatibility, and similarity with tissue and cell environments. Over the past decade, hydrogels have developed from static materials to “smart” responsive materials adapting to various stimuli, such as pH, temperature, chemical, electrical, or light.

Besides biomedical applications, this makes them useful materials in soft robotics as well as responsive and programmable materials that can be used for catalysts, chemical detectors, and absorbents for carbon capture.

Hydrogels can be physical, chemical, or biochemical. Physical gels can undergo a transition from liquid to a gel in response to a change in environmental conditions such as temperature, ionic concentration, pH, or other conditions such as mixing of two components. Chemical gels use covalent bonding that introduces mechanical integrity and degradation resistance. Biochemical hydrogels contain biological agents like enzymes or amino acids that participate in the gelation process.

The three integral parts of hydrogel preparation are monomer, initiator, and cross-linker.

In general, hydrogels can be prepared from either synthetic polymers or natural polymers. These polymers can be cross-linked to form hydrogels in a number of ways: Linking polymer chains via chemical reaction; using ionizing radiation to generate main-chain free radicals which can recombine as cross-link junctions; and physical interactions such as entanglements, electrostatics, and crystallite formation.

In general, hydrogels can be prepared from either synthetic polymers or natural polymers. These polymers can be cross-linked to form hydrogels in a number of ways: Linking polymer chains via chemical reaction; using ionizing radiation to generate main-chain free radicals which can recombine as cross-link junctions; and physical interactions such as entanglements, electrostatics, and crystallite formation.

Based on the methods of preparation, hydrogels may be classified as homopolymer, copolymer, semi-interpenetrating network (semi-IPN) and interpenetrating network (IPN).

Homopolymeric hydrogels are referred to polymer network derived from a single species of monomer, which is a basic structural unit comprising of any polymer network. Copolymeric hydrogels are comprised of two or more different monomer species with at least one hydrophilic component, arranged in a random, block or alternating configuration along the chain of the polymer network. Multipolymer interpenetrating polymeric hydrogel (IPN), an important class of hydrogels, is made of two independent cross-linked synthetic and/or natural polymer component, contained in a network form. In semi-IPN hydrogel, one component is a cross-linked polymer and other component is a non-cross-linked polymer. Read more from Nanowerk