How to deal with dead car batteries from electric cars?

With over a billion cars in the world today, and larger percentages expected to be electric, the question of what to do with the millions of hazardous unusable car batteries is essential.

A Massachusetts startup is transforms old electric car batteries into better-than-new ones

The following written content from Bruce Gellerman

The switch to electric vehicles is accelerating worldwide. There are about 10 million battery-powered vehicles on the road today, and by the end of the decade, the International Energy Agency predicts there could be 230 million.

But there’s a problem down the road. All those EVs are powered by batteries, and when they come to end of their life cycles, they could end up as toxic trash.

The world needs better ways to deal with dead batteries.

Now, a Massachusetts startup has a unique solution that gives the worn-out energy cells new life, making EVs more sustainable — and cheaper, too.

Ascend Elements claims it can turn spent lithium-ion batteries into ones that are better than new — longer-lasting, faster-charging and less-polluting. The recycled energy cells could also provide the U.S. with an added measure of energy independence.

Driving Change

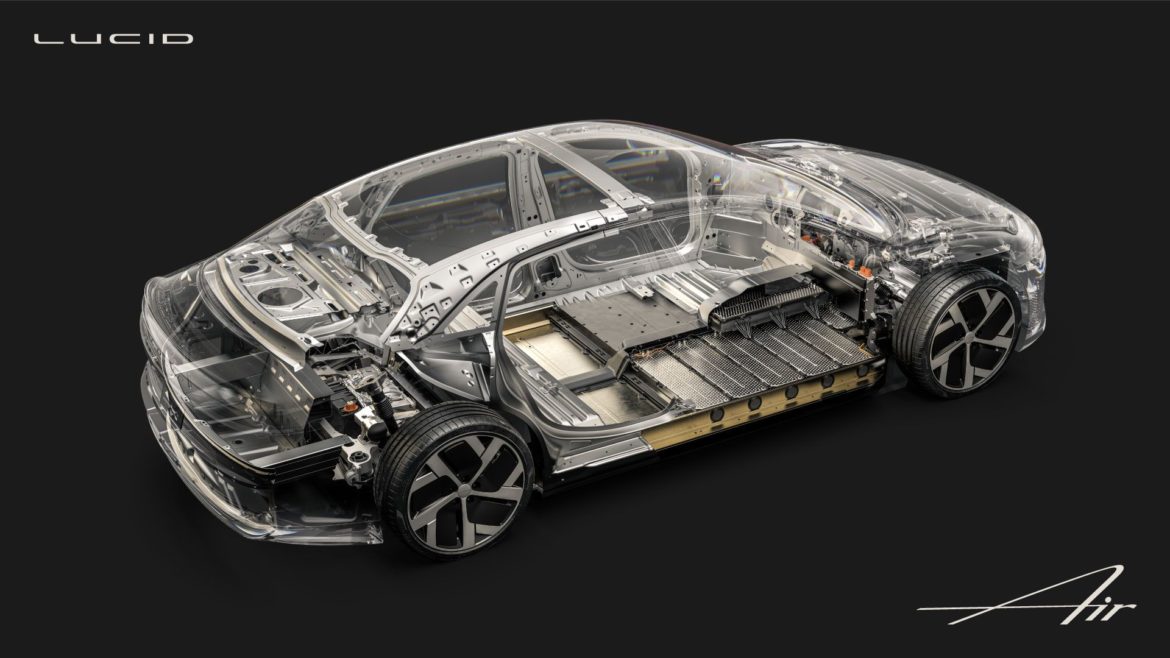

Lithium-ion batteries are in the vast majority of electric cars and trucks. Lithium is what scientists call “energy dense,” packing a powerful punch relative to its size and weight. But the battery name is misleading.

“Ironically, lithium is not the most important material in a lithium-ion battery,” says Jeffrey Spangenberger, director of Argonne National Laboratory’s ReCell Center, which works to advance battery-recycling technologies.

Nickel, graphite, manganese and cobalt are also important, Spangenberger says, especially cobalt, the most expensive material in EV batteries. It’s one reason the batteries are the costliest part of an electric vehicle.

Those metals are mostly mined overseas. Australia and South America have vast lithium deposits, but the extraction process uses billions of gallons of water a year and can devastate the environment. The largest reserves of cobalt are found in the Democratic Republic of the Congo, where miners have faced working conditions that violate human rights.

The mined minerals are largely processed in China and then shipped to the rapidly growing number of factories around the world that produce EV batteries.

That long and uncertain supply chain is also a growing strategic concern for the U.S. So, reclaiming the valuable metals in spent EV batteries is becoming a national priority.

“Without [battery] recycling, electric vehicles are going to be a challenge to get off the ground,” says Spangenberger. Argonne’s ReCell Center, part of the Department of Energy, is collaborating with academic institutions and companies to find new ways to reclaim and reuse the valuable battery metals.

One of those research facilities is professor Yan Wang’s lab at Worcester Polytechnic Institute.

For centuries, high-temperature furnaces have been used to smelt metals, separating out the desired components. About 10 years ago, Wang and postdoctoral student Eric Gratz began investigating an entirely new process.

“Not many people were working on [battery] recycling,” says Wang. “But today, lithium battery recycling is one of the hottest topics in the battery field.”

Wang and Gratz co-founded a company based on their patented recycling process. Over the years, the company has grown from bench science to industrial scale.

The newly renamed company, Ascend Elements, now based in Westborough, takes thousands of pounds of lithium-ion batteries from cellphones, power tools, laptops and EVs and shreds them. The batteries don’t need to be sorted, which simplifies the recycling process.

Black Mass And Alchemy

Once the shredded material goes through a series of sieves, it emerges as a fine powder known as “black mass.”

“That’s essentially where all the value is,” says Roger Lin, Ascend’s vice president of global marketing and government relations.

The process, called “Hydro-to-Cathode,” takes about a week to extract the impurities from the powder, leaving behind vats filled with valuable EV metals, according to the company. It also recovers almost 100% of the metals and produces no toxic waste.

“This is alchemy,” says Lin. “We call it chemistry but it’s alchemy.”

The company’s secret sauce is in adjusting the metal mixture, atom-by-atom, to get the exact ratio of materials. The finished product, called a battery cathode, can be customized to an EV manufacturer’s specific needs.

“This is alchemy. We call it chemistry but it’s alchemy.”

ROGER LIN

Ascend Elements calls it “upcycling,” as opposed to recycling, because the active materials are turned into a value-added manufactured product. And the company claims that the upcycled cathodes perform better than new batteries in some significant ways.

“I was surprised,” says Wang. “We can charge [the upcycled batteries] … two or there times faster.”

The upcycled batteries also last longer, he says, and can be charged many more times than the original ones.

“We can have at least a 30% [longer] life cycle,” Wang says. “Before you had a 10-year life [cycle]; now you can have 13 or 15 years of life.”

That means fewer spent lithium-ion batteries dumped in landfills where they can spontaneously ignite and explode, or leach toxic metals into groundwater.

The unexpected findings were recently published in the peer-reviewed science journal, Joule, and independently verified in other labs, says Gratz. He’s now Ascend Elements’ chief technology officer.

“That’s kind of the biggest takeaway because people automatically assume recycled materials won’t perform as well but we found it’s actually the opposite,” Gratz says.

He adds that their process results in 93% lower carbon emissions at about half the cost of newly mined metals.

“You’re not shipping material from China … so you’re easing the supply chain [and] reducing greenhouse gases,” Gratz says.

In June, Ascend Elements announced an agreement with Honda to provide the carmaker with new cathodes made from old lithium-ion batteries. And Ascend plans to build what will likely be the largest battery recycling plant in North America — not in New England, but Georgia. (Many battery factories and EV assembly plants are planned in the South.)

The company has attracted $90 million from investors, offering them a generous vision of the future. According to Andrew Aberdale, Ascend’s chief financial officer, compared to a standard metal recovery process, the payoff is “in the range of 10 times the revenue and three times the amount of profit.”

Ascend Elements is just one of several companies that the Department of Energy’s Argonne National Lab is providing with startup funding to find new ways to reuse materials in EV batteries. Spangenberger says old EV batteries that are worn, but still retain 80% of their energy-storage capacity, can also be reused to store renewable energy generated by wind and solar power.

As the EV industry itself is still relatively new, there’s a shortage of worn-out batteries to recycle, says Spangenberger. But the supply will build quickly.

“We’re in a really good position to make this a huge opportunity for the United States in the next several years as we take these vehicles and batteries offline,” he says.

Massachusetts’ goal is to have 1 million EVs on the road by the end of the decade, and the state plans to ban the sale of gas vehicles by 2035.

Batteries are driving the future. Now — before their life cycles’ end — is the time to ensure the technology is sustainable, Spangenberger says. Read more from Wbur

The following written content from BBC

Subscribe Here

How to deal with dead car batteries from electric cars?

With over a billion cars in the world today, and larger percentages expected to be electric, the question of what to do with the millions of hazardous unusable car batteries is essential.

The following written content from Emma Woollacott from an earlier post

He’s talking about the market for electric cars in Europe.

By 2030, the EU hopes that there will be 30 million electric cars on European roads.

“It’s something that’s never really been done before at that rate of growth for a completely new product,” says Dr Anderson, who is also the co-director of the Birmingham Centre for Strategic Elements and Critical Materials.

While electric vehicles (EVs) may be carbon neutral during their working lifetime, he’s concerned about what happens when they run out of road – in particular what happens to the batteries.

“In 10 to 15 years when there are large numbers coming to the end of their life, it’s going to be very important that we have a recycling industry,” he points out.

While most EV components are much the same as those of conventional cars, the big difference is the battery. While traditional lead-acid batteries are widely recycled, the same can’t be said for the lithium-ion versions used in electric cars.

EV batteries are larger and heavier than those in regular cars and are made up of several hundred individual lithium-ion cells, all of which need dismantling. They contain hazardous materials, and have an inconvenient tendency to explode if disassembled incorrectly.

“Currently, globally, it’s very hard to get detailed figures for what percentage of lithium-ion batteries are recycled, but the value everyone quotes is about 5%,” says Dr Anderson. “In some parts of the world it’s considerably less.”

Recent proposals from the European Union would see EV suppliers responsible for making sure that their products aren’t simply dumped at the end of their life, and manufacturers are already starting to step up to the mark.

Nissan, for example, is now reusing old batteries from its Leaf cars in the automated guided vehicles that deliver parts to workers in its factories.

Volkswagen is doing the same, but has also recently opened its first recycling plant, in Salzgitter, Germany, and plans to recycle up to 3,600 battery systems per year during the pilot phase.

“As a result of the recycling process, many different materials are recovered. As a first step we focus on cathode metals like cobalt, nickel, lithium and manganese,” says Thomas Tiedje, head of planning for recycling at Volkswagen Group Components.

“Dismantled parts of the battery systems such as aluminium and copper are given into established recycling streams.”

Renault, meanwhile, is now recycling all its electric car batteries – although as things stand, that only amounts to a couple of hundred a year. It does this through a consortium with French waste management company Veolia and Belgian chemical firm Solvay.

“We are aiming at being able to address 25% of the recycling market. We want to maintain this level of coverage, and of course this would cover by far the needs of Renault,” says Jean-Philippe Hermine, Renault’s VP for strategic environmental planning.”We are aiming at being able to address 25% of the recycling market. We want to maintain this level of coverage, and of course this would cover by far the needs of Renault,” says Jean-Philippe Hermine, Renault’s VP for strategic environmental planning.

“It’s a very open project – it’s not to recycle only Renault batteries but all batteries, and also including production waste from the battery manufacturing plants.”

The issue is also receiving attention from scientific bodies such as the Faraday Institution, whose ReLiB project aims to optimise the recycling of EV batteries and make it as streamlined as possible.

“We imagine a more efficient, more cost-effective industry in future, instead of going through some of the processes that are available – and can be scaled up now – but are not terribly efficient,” says Dr Anderson, who is principal investigator for the project.

Currently, for example, much of the substance of a battery is reduced during the recycling process to what is called black mass – a mixture of lithium, manganese, cobalt and nickel – which needs further, energy-intensive processing to recover the materials in a usable form.

Manually dismantling fuel cells allows for more of these materials to be efficiently recovered, but brings problems of its own.

“In some markets, such as China, health and safety regulation and environmental regulation is much more lax, and working conditions wouldn’t be accepted in a Western context,” says Gavin Harper, Faraday Institution research fellow.

“Also, because labour is more expensive, the whole economics of it make it difficult to make it a good proposition in the UK.”

The answer, he says, is automation and robotics: “If you can automate that, we can pull some of the danger out of it and make it more economically efficient.”

And there are indeed powerful economic arguments for improving the recyclability of EV batteries – not least, the fact that many of the elements used are hard to come by in Europe and the UK.

“You’ve got the waste management problem on the one hand, but then on the flip side of that you’ve also got a great opportunity because obviously the UK doesn’t have indigenous supplies of many factory materials,” says Dr Harper. Read more from BBC“You’ve got the waste management problem on the one hand, but then on the flip side of that you’ve also got a great opportunity because obviously the UK doesn’t have indigenous supplies of many factory materials,” says Dr Harper. Read more from BBC